Our Services

Over the last two decades, we have consistently solved the most pressing environmental challenges regardless of project complexity, industry, or contaminant.

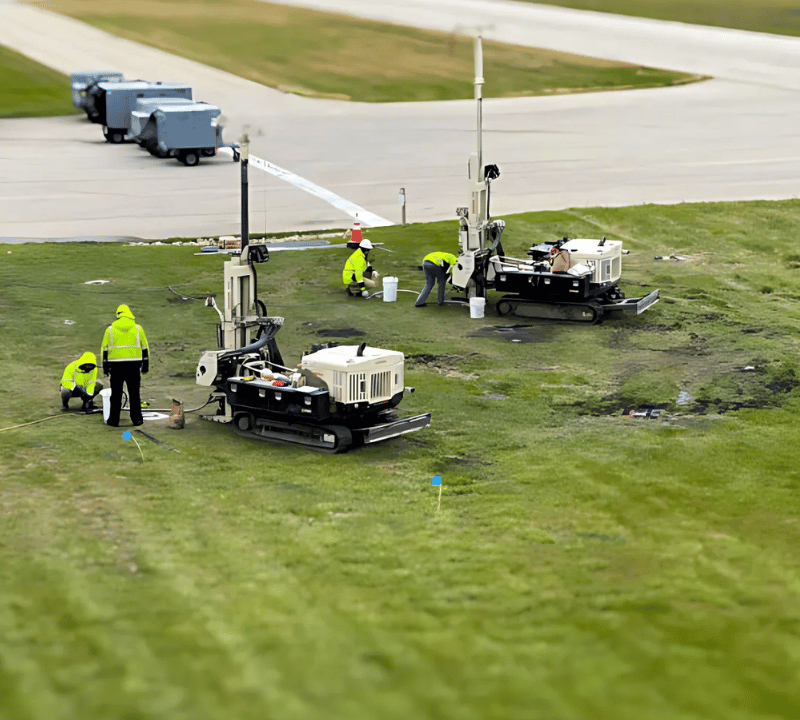

Remediation

ORIN provides comprehensive environmental remediation services using innovative in-situ and ex-situ treatment methods for soil, groundwater, and industrial contamination.

Wastewater

ORIN delivers cutting-edge wastewater treatment solutions using BAM technology and specialized microbes to remove PFAS, metals, and other contaminants from industrial effluent.

Chemistries

ORIN develops and implements specialized treatment chemistries, including BAM, oxidation solutions, and bio-remediation compounds for complex environmental challenges.