Injection

Injection

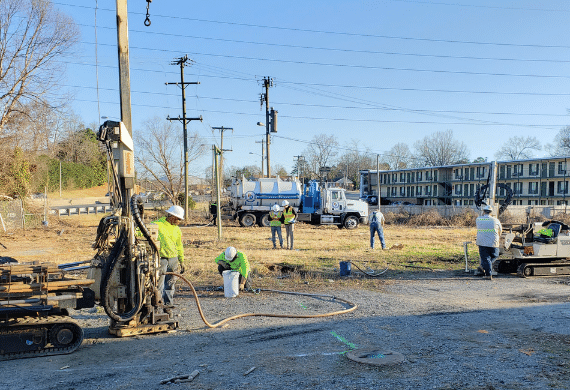

ORIN offers in-situ remediation services by injecting treatment chemistries directly into the contaminated zone of the formation. In-situ applications are performed through either a direct push injection or permanent point injection.

What Sets Us Apart

ORIN’s industry leading experience delivers innovative problem-solving designs that will meet the needs of our clients. ORIN uses state of the art equipment that permits injection of treatment solutions tailored to the exact needs of the site. The combination of our expertise and resources allows ORIN to flexible in any given situation.

ORIN’s purpose-built trailers are designed for continuous injection at multiple locations within the site. This advantage provides an efficient application of the treatment chemistry saving time and money. The project trailers contain all necessary treatment chemistry blending and delivery equipment. ORIN uses pneumatically driven chemical resistant pumps and equipment. Our purpose-built equipment allows for continual monitoring or flow rate, pressure, and total volume. Shut-off valves and spill/leak containment systems are positioned at numerous locations throughout the delivery system ensuring safe operations.

Treatment Approaches

- In-Situ Absorption & Degradation (BAM)

- In-Situ Chemical Oxidation (ISCO)

- In-Situ Chemical Reduction (ISCR)

- Reductive Dechlorination

- Bioaugmentation

- Metals Stabilization

Common Contaminants

- Per – and Polyfluoroalkyl Substances (PFAS)

- Petroleum Hydrocarbons

- Chlorinated Solvents

- Fuel Oils

- Coal Tars

- Pesticides

- Heavy Metals

Inject-and-Extract

Vacuum extraction can be incorporated to facilitate removal of contaminated groundwater and/or non-aqueous phase liquid (NAPL) while also assisting in treatment chemistry application. As the treatment chemistry contacts adsorbed contaminants, they may become mobilized thus more easily recovered. Any contaminant that is recovered via vacuum extraction will result in less demand on the treatment chemistry and more complete destruction of the COC.

Extraction also provides ORIN with hydraulic control during the injection. The treatment chemistry can be drawn towards the most heavily impacted areas. Extraction will help to prevent excessive mounding of the groundwater reducing the risk of liquids daylighting to the surface.

Offering The Best Environmental Remediation And Wastewater Solutions

ORIN Technologies specializes in oxidation, bioremediation, reduction, and advanced oxidation processes (AOPs) to address specific issues in remediation and water treatment.

Contact Us

- 405 Investment Court, Verona, WI 53593

- Phone: (608) 838-6699

- Fax: (608) 838-6695

- Email: [email protected]

- Web: orinrt.com